4-Gallon Tumble-Basket Blast Cabinet Boosts Productivity 400% for Firearm-Accessory Manufacturer—In One Week

4-Gallon Tumble-Basket Blast Cabinet Boosts Productivity 400% for Firearm-Accessory Manufacturer—In One Week

Owner of ACCU-TAC says manual blasting jobs that took five hours now only take one hour.

“I’ve been looking a long time for a solution like this,” says Felipe Salazar, owner of ACCU-TAC, about his new Clemco 4-Gallon Tumble-Basket Blast Cabinet. ACCU-TAC manufacturers high-end firearm bipods, scope rings, and other firearm accessories. “We had been running two Raptor manual blast cabinets with two operators, with overtime and even nightshifts” Felipe explains. “But now with our new Clemco cabinet, it’s so efficient that most days we run out of parts to put in it. It won’t be long until the machine pays for itself.”

Felipe goes on to explain that blasting that would take five hours with two operators each working one of the Raptor manual cabinets now takes one hour in ACCU-TAC’s new 4-Gallon Clemco Cabinet. “That’s a 400% increase in productivity!” Felipe exclaims. “And we’ve had the machine only a little over a week!”

A Huge Savings in Labor Costs

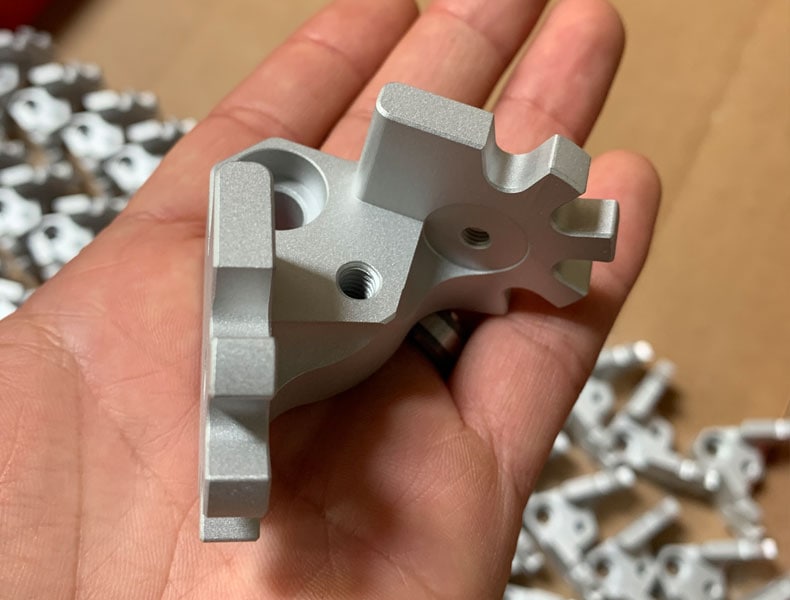

ACCU-TAC’s 4-Gallon Tumble-Basket Blast Cabinet arrived the first week of August. It uses fine glass bead to finish batches of parts usually less than an inch long, many of the parts the size of marbles. The parts are components in rifle bipods, the bread and butter of ACCU-TAC’s business. Typically, ACCU-TAC’s shop runs six 10-minute batches or four 15-minute batches of these parts per hour to remove machine marks and create a matte finish, for a total of about 1,300 parts an hour.

“We are still experimenting with the process,” Felipe shares,” but it’s important that we do everything in house so that we maintain control over quality and delivery time, and blasting is essential to our process. Blasting with our Clemco cabinet is a huge savings in labor costs, and the quality of the cabinet’s construction and output are outstanding. I’m loving it.”

A State-of-the-Art Shop

“Felipe runs a state-of the art shop with a CAD/CAM system and 12 Haas CNC machines” says Sean Jewett, who has worked for 15 years at Kleen Blast and currently works at its location in Rancho Cucamonga, Calif., where ACCU-TAC also is located. Kleen Blast is a Clemco distributor and one of the West Coast’s largest distributors of abrasive blasting media and equipment, and it has four other locations on the West Coast. “I showed Felipe videos Clemco has on its website on how to operate and set up the 4-Gallon Tumble Cabinet in addition to Clemco’s print literature,” Sean explains. “I knew the machine would be a great fit for Felipe because his business is growing so fast, and he is dedicated to using automation.”

ZERO 4-Gallon Tumble-Basket Blast Cabinet

I Felt I Could Make Better Equipment

ACCU-TAC’s firearm accessories now are sold across the United States and in 28 countries around the globe, as far away as Australia. But it wasn’t always that way.

“I’ve always been a gun enthusiast,” Felipe says, “but shooting gear can get so expensive, and sometimes the quality isn’t there. In my twenties I worked in machine shops, and I felt I could make better equipment for myself, so I made my own bipod. People at the shooting range I went to asked me about it. They ended up being my first customers.”

Felipe went on to sell his bipods on eBay, began cold calling local gun shops, and then renting booths at weekend gun shows. Sales grew. In 2015, Felipe formally incorporated ACCU-TAC, and now ACCU-TAC has 15 employees.

I Still Work in the Shop

“I still work in the shop when I can,” Felipe says. “Because machining was my first profession, I knew I could make high-quality firearm accessories people would want. I’m grateful to the people who have supported me along the way and to Clemco and Sean at Kleen Blast for helping me jump to the next level. I will be buying several bigger Clemco cabinets soon.”